DSPAUT

DSVision

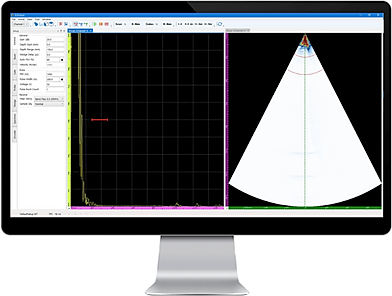

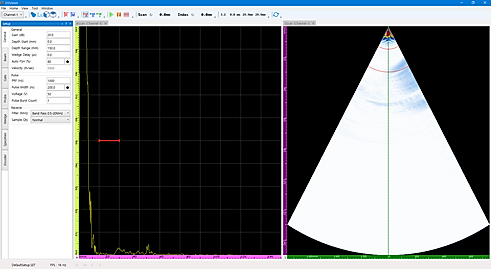

PC PAUT PROGRAM - DSVISION

DSVision is a program designed for desktop PCs and laptops.

You can receive inspection data through a LAN cable and check the images through the Viewer

without having to leave your workspace.

Furthermore, it can be utilized effectively in automated systems.

SETTING MENU

GENERAL

This contains a list of general settings such as Gain, Range, and Wedge delay.

BEAM Menu

The Beam settings are used for configuring the ultrasound for internal inspection.

You can use various functions such as shape, range, and focusing of the ultrasonic beam.

CHANNEL TYPE

The Channel Type menu contains preset focal law configurations for the beam

which can be directly selected from the list.

Through this menu, you can freely switch between Sectorial scan, Linear scan, TOFD,

and Conventional channel types.

SCAN VIEW LAYOUT

You can add or change different layouts of the scan windows you want displayed on the screen.

They consist of A-scan, S-scan, C-scan, and B-scan, and are applied immediately when selected.

GATE

The Gate is used to examine the signal data from defects such as the position values.

MEASURE TOOL

The Measure Tool displays information about the values on screen.

You can see the A, B, I values of the gate and the position values of the reference/measurement bar.

PROBE

The Probe tab is where you input the parameters of the ultrasonic sensor you are using.

These parameters include frequency, pitch, number of Tx/Rx, and you can manipulate

the probe position through the offset and skew angle.

WEDGE

The Wedge tab is where you can input the wedge angle information of the ultrasound beam.

You can enable or disable the wedge, configure the wedge angle, velocity, initial height, and primary values.

SPECIMEN & WELD

The Specimen & Weld menu can simulate the shape of the inspection target on the S-scan to help detect defects.

You can change the weld shape (V/Reverse V/Double V) and input the material parameters of the specimen such as velocity in material, thickness, and length.

ENCODER

This menu is for inputting the parameters of an external encoder. It supports 2 axes

and recognizes Scan and Index directions.

Scan and Index determines the start/end position values of the encoder, resolution value, and the scanner type.

CALIBRATION

VELOCITY CALIBRATION

DSVision supports a variety of calibrations.

The Velocity calibration sets the correct value for the speed of sound in a specific material.

WEDGE DELAY CALIBRATION

This corrects the Wedge Delay value for the entire vector.

Wedge delay calibration helps achieve more precise detection by adjusting the position value of the signal to match the reference value.

SENSITIVITY CALIBRATION

This can be adjusted through calibration to generate a more uniform sensitivity throughout the signal of the entire beam vector.

The Auto Sensitivity Calibration window helps you to calibrate the signal's Amplitude (height) value to the baseline.

ENCODER CALIBRATION

Each axis can be calibrated separately, and you can use it to calibrate the encoder resolution.

FEATURES

FLIP/SWAP

You can change the image orientation to horizontal, vertical, or rotate by 90 degrees.

ZOOM

You can zoom into any part of the scan screen.

Zoom in on the desired window to measure the exact size of the defect, and click Zoom Reset to return to the original state.

CHANNEL GROUP

Channel Group is a function that can acquire images from multiple probes.

The group function can be configured under Beam settings, and clicking Add / Remove applies to the topmost channel in the list.

SAVE & LOAD

DSVision can save all parameter values, and can directly call saved setting values through Load.

Under Beam settings, you can select a default layout from Group Base, but you can also save and load a custom layout through Save Layout / Load Layout.

WINDOW LAYOUT

All windows can be repositioned and moved freely to create the desired layout that feels most convenient for the user.

CORROSION Inspection